R.M. Waxroll

R. M. Wax rolls

The wax-rolls for various autoconers are being manufactured with latest plant and machinery with best skills for maintaining the quality and dimension accuracies with best possible standard.

The various qualities of specialized waxes as per the required quality norms are used, from international quality manufacturers.

The waxes are subjected to various accurately defined manufacturing process like –

Controlled heating and blending

Automated pouring and casting the molds, heating and cooling under stringent temperature controlled conditions.

The most accurate engineered process of finishing, milling, grading, quality control and packing system is used

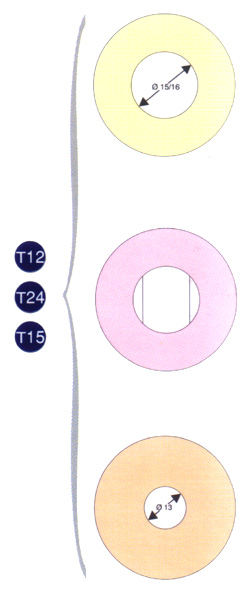

|

|

___________________________________________________________

|

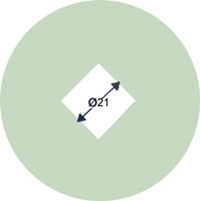

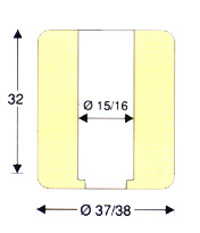

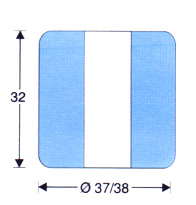

OE Investa |

|

____________________________________________________________

|

|

|

|

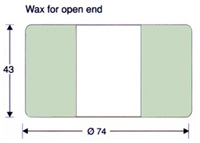

Muratta |

|

|

|

|

|

|

|

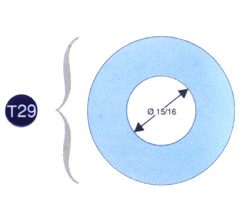

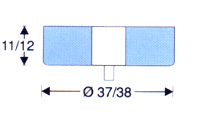

W.Schlafhorst Autocoro+Autoconer ASavio e Autosuk |

||

Features

Why waxing is needed:

Application of proper waxing results in the production of better quality yarns by reducing friction coefficient and giving antistatic characteristics to the yarn.

Through proper waxing, a uniform yarn tension is maintained throughout the knitting operation to obtain optimum productivity.

Major Effect of Waxing:

1. Protects yarns from friction coefficient in knitting operation.

2. Impart better feel and lusture to the yarn.

3. Increase tension strength of yarns.

4. Make yarn smooth and flexible.

5. Protects yarns from static charges.

6. Reduces friction coefficient.

7. Reduces loose fibers.

8. Effect steam setting.

Special features of RM wax Rolls:

- We ensure the HARDNESS and SOLUBILITY of R.M. WAX ROLLS will avoid uneconomical consumption and will result cost saving

- R. M. Wax Rolls are manufactures with special type of waxes for yarn. It has very high melting point and Hardness, so that the wax particles on the waxed yarn can be resistant to the heat.

- R.M. WAX ROLLS can also be supplied with certified food grade waxes formulation if specifically asked for.

- R.M. WAX ROLLS are Eco friendly and biodegradable

- R.M. WAX ROLLS are free from silicones.

- R.M. WAX ROLLS are free from Hazardous chemicals like penta chloro phenol (PCP).

Application / Effect of coefficient of Friction on Yarn:

For the most effective and economical use of R.M. wax rolls, the optimum amount of wax adhered to yarn is approximately 0.05% – o.15% on yarn Weight. Remember that within this range, the frictional resistance reduces greatly and The machine processes can be managed effectively.

|

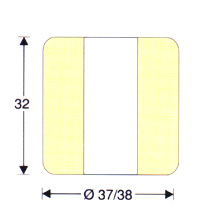

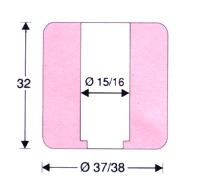

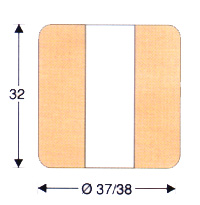

Technical Specification of Various Qualities of Wax washers |

|||||

| Sr. No. | Type | colour | Melting Point Deg 25o C | Penetration at 25o C | Range of use |

| 1 | R.M 300 | Green | 58-60 | 21-23 | For soft twist yarns & bleached yarn at low winding tension # |

| 2 | R.M 400 | Blue | 60-62 | 19-20 | Almost universal application for cotton, wool, rayon & for normal wax applications # |

| 3 | R.M 600 | yellow | 62-64 | 10-11 | For yarns finer than 60 Nm (cotton/Synthetic) & also where department conditions are more than 30o C & for low wax application # |

| 4 | R.M 800 | Orange | 63-65 | 10-11 | Suitable for yarn conditioning /steam setting machines after waxing # |

| 5 | R.M 1000ws | pink | 61-63 | 15-17 | Water soluble for fabrics which are subsequently dyed or bleached & for normal wax application ## |

Note : The above qualities have been standardized for qualities in general accepted by various Export oriented units, based on their feedback. If any company needs special quality for their specific Wax Consumption / Application level, Came can be formulated to their requirement, if feedback is given for the same based on practical trial of these qualities in their plant.

Mark # > These waxes are water soluble by adding emulsifying agents during finishing

## > These waxes are directly water soluble due to emulsifier contained in the waxes.

Mavani Synthetic Lubricants Pvt Ltd.

Tel: 91-422-4368578/2547739/2546836